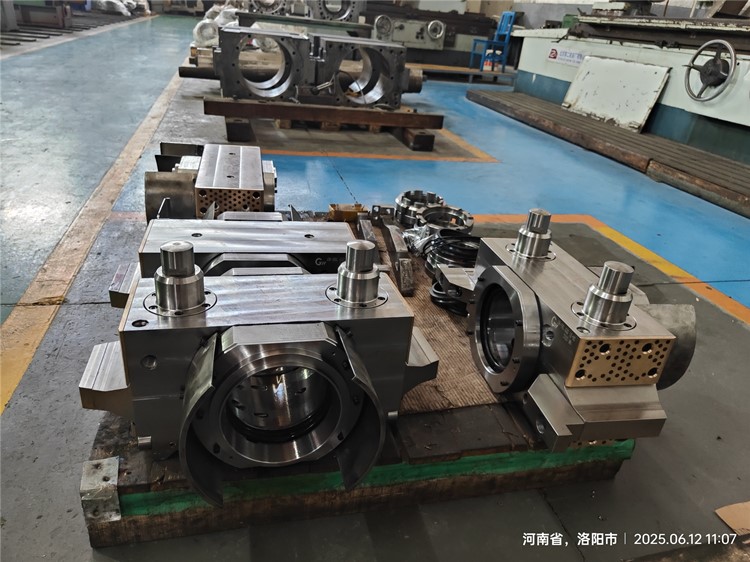

Rolling mill Work roll and Back-up roll chocks reconditioning Service

About Us

Rolling mill chocks are the maximum stressed bearing component in a manufactured item, and so are most liable to consistent the financial losses incurred as a result of chock failure will be far greater than the actual value of the chock.

Neglected back-up roll chocks may be found in strip mills around the world. Bore concentricity or ovality, coupled with excessive clearances resulting from wear and fretting corrosion of sliding surfaces can escalate quickly, leading to premature bearing failures. The further result is poor product quality, seen specifically in the strip surface conditions, and shape and profile tolerances.

Our thorough repair process includes: premachining surfaces to ensure quality welds; expert welding; BoreGuard™ Arc Wire Spray Welding; stress relieving; and precise finish machining to ensure proper contact surfaces. To ensure top performance, bore diameters are verified and the width of shim liners is set. Final steps in the refurbishment process are inspection; deburring and sanding; cleaning and painting; careful reassembly, including bearing load zone rotation, and packing for shipping to ensure chocks arrive in perfect condition. Our rigorous repair process pays off. Chocks we have refurbished are returned in as-new or betterthan-new condition, regularly providing longer service runs with less downtime. Our innovative processes and manufacturing techniques reduce long-term maintenance costs. Our technical modifications improve reliability and performance.