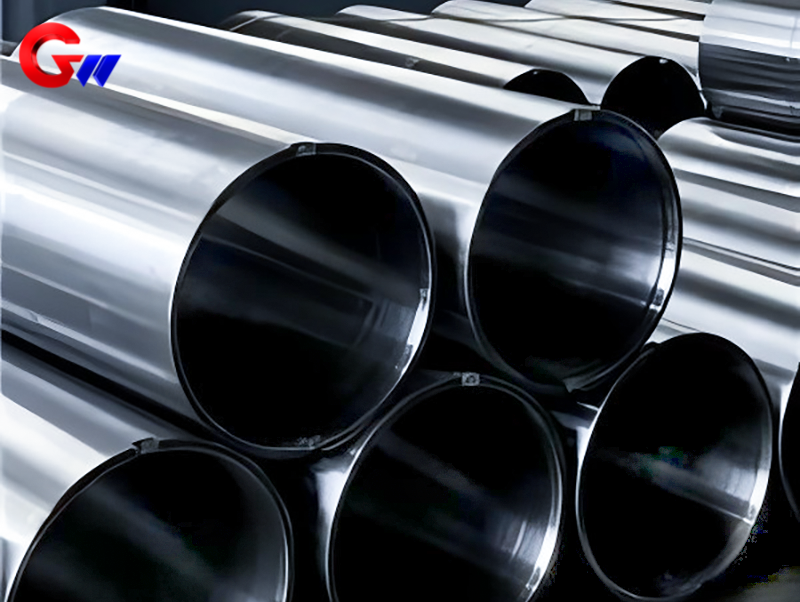

Cast steel sleeve for copper strip rolling mill

The copper strip rolling mill has extremely high requirements for the wear resistance, thermal conductivity, and anti bite performance of the sleeve, and the casting steel spool needs to meet the requirements of high-precision rolling and long-term stable operation.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Cast steel sleeve for copper strip rolling mill

Product Information

| Application | Sleeve Material | Specification |

| colored aluminu strip mill steel sleeve | ZG310-570 | Φ 665 * 605 * 1900 mm |

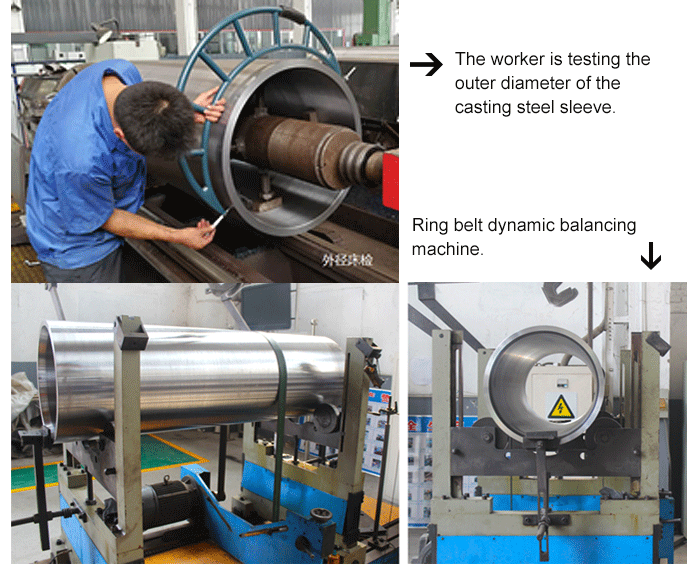

Mechanical processing standard for casting steel spool used in copper strip mills

Parameter requirements for testing equipment

Internal hole precision IT6 level (H6) pneumatic instrument

Cylindricity ≤ 0.008mm/200mm roundness tester

Dynamic balancing grade G1.6 (ISO 1940) high-speed dynamic balancing machine

Surface roughness Ra ≤ 0.4 μ m (precision rolling area) profilometer

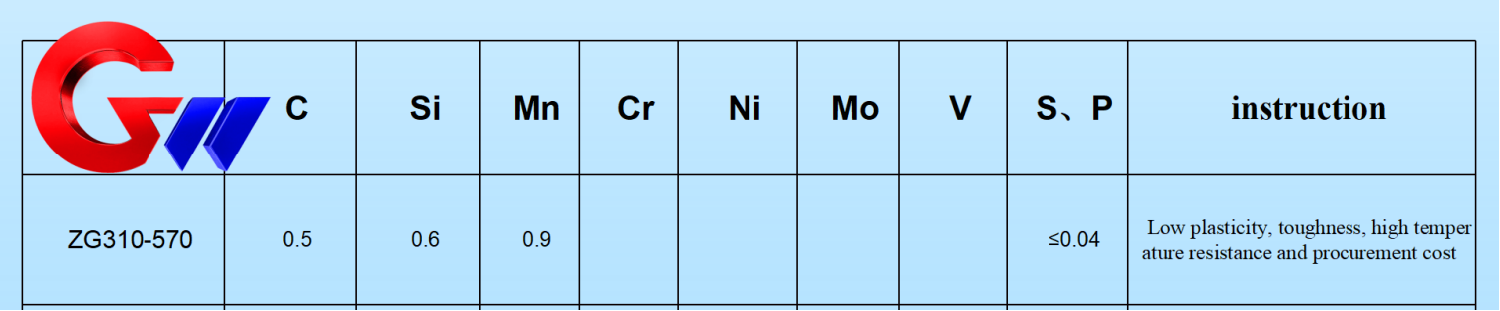

Mechanical properties of casting steel spool for copper strip rolling mill (ZG35CrMo quenched and tempered state)

Typical value testing standards for indicators

Tensile strength (Rm) 850-950MPa GB/T 228.1

Yield strength (Rp0.2) 650-750MPa GB/T 228.1

Elongation rate (A) ≥ 16% GB/T 228.1

Impact energy (20 ℃) ≥ 45J GB/T 229

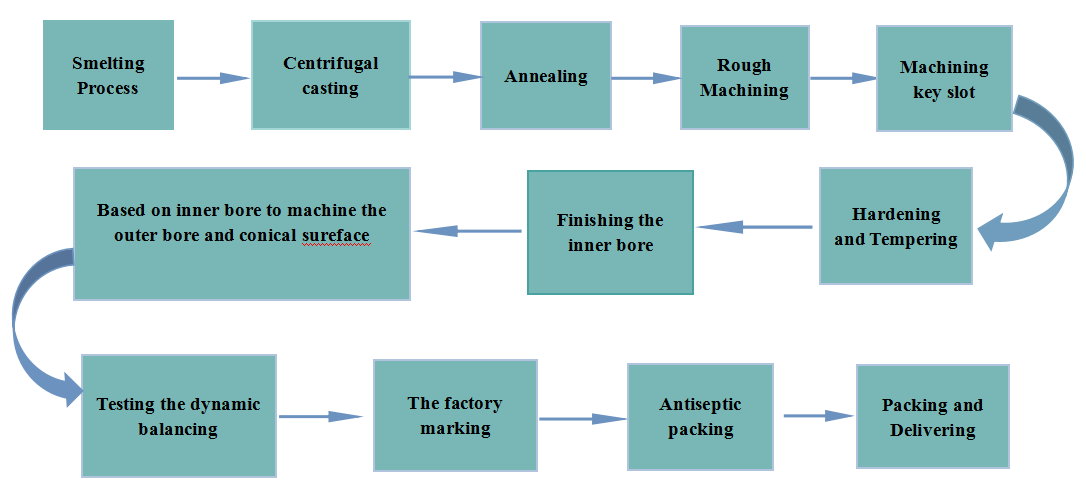

Description of heat treatment of GW precision casting steel spool

We will conduct heat treatment strictly for steel spool which have the specific demand in mechanical property, also in corresponding testing of the mechanical property, make sure every product to achieve the best condition and customers’ good results.

We used our independent dedicated device-hole drilling machine which is researched and developed by ourselves, it also obtain the national patent. The machine is provided with good rigid, no returning clamp and machine and high accuracy on the processing of machining. Through continuous improvement, our company formed a integrated processing technic system to ensure concentricity, cylindricity, degree of symmetry and dynamic balance of the casting steel spool. Specific accuracy tolerance and geometric accuracy tolerance is strictly according to the customers’ requires.

100% Dynamic Balancing Test

In terms of inspection, in order to safeguard the benefits of customers and ensure better quality of casting steel spool products, we have conducted various tests on mechanical properties after heat treatment in addition to conventional dimensional inspection.Ring belt dynamic balancing machine can be 100% dynamic balancing test.

Packing

We have excellent packaging team and mature packaging technology for our casting steel spool.

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.

Our casting steel spool products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any casting steel spool spindle repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!

guangwei@gwspool.com or +86-379-64593276

Related Products