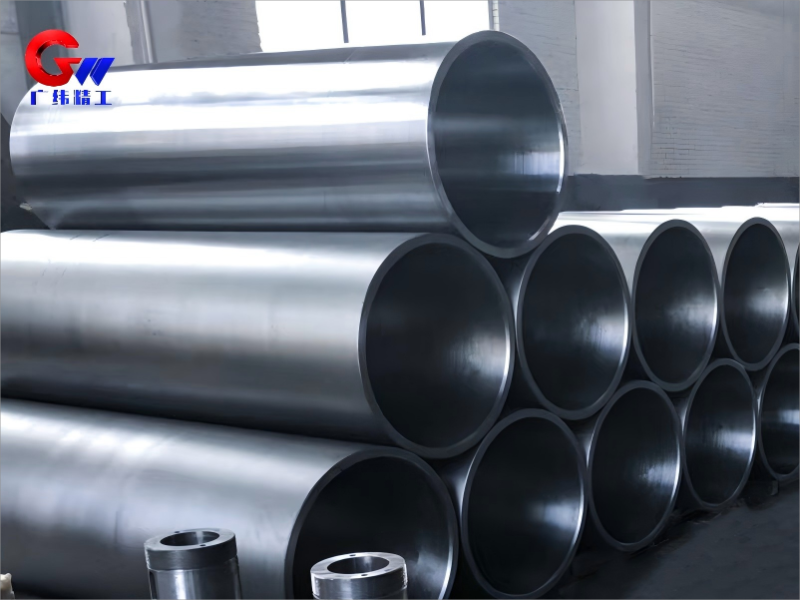

Customized 35CrNiMo Steel Sleeve Of Aluminum Sheet And Strip Mill Machine

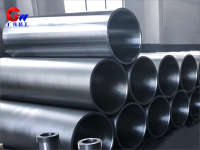

35NiCrMo is often to use for customized 35CrNiMo steel sleeve of aluminium sheet and strip. There are many specifications of GW precision steel sleeves, one of the specification is 565*505*1450.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Customized 35CrNiMo Steel Sleeve Of Aluminum Sheet And Strip Mill Machine

Casting steel 35NiCrMo is often used for steel sleeve of aluminium sheet and strip. There are many specifications of GW precision steel sleeves, one of the specification is 565*505*1450.

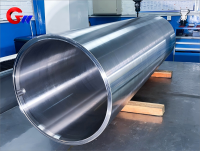

The 35CrNiMo steel sleeve used in aluminum plate and strip rolling mills is a customized core component with high strength and wear resistance, mainly used for roll neck protection of supporting rolls or working rolls, ensuring rolling accuracy and stability.

Application scenario of customized 35CrNiMo steel sleeve for aluminum strip rolling mill

Aluminum plate and strip rolling production line

Function: Protect the roll neck of the rolling mill, withstand rolling forces (usually 500~3000 tons), alternating loads, and slight impacts (such as the moment of aluminum strip biting).

Characteristics of working conditions:

Temperature: 60-120 ℃ (Aluminum strip has fast thermal conductivity and low frictional heat, but local heating may occur due to poor lubrication).

Corrosion environment: Contact with rolling oil or emulsion, requiring resistance to slight chemical corrosion.

Coordination requirements: It should have an interference fit with the roll neck (interference fit of 0.03~0.08mm) and high dimensional stability.

Special needs

The surface quality of aluminum strip requires extremely high standards, and the sleeve needs to avoid micro cracks or peeling that may cause contamination of the rolling mill.

Material selection for customizing 35CrNiMo steel sleeve for aluminum strip rolling mill: 35CrNiMo steel

Composition optimization (special adjustment for aluminum rolling mill):

C: 0.32~0.38% (slightly lower than that used in copper rolling mills, improving toughness), Ni: 1.40-1.60% (enhanced low-temperature toughness).

Performance advantages:

Tensile strength ≥ 950MPa, impact energy ≥ 60J (-20 ℃).

High fatigue strength (10 cycles stress ≥ 450MPa).

Customized heat treatment process for 35CrNiMo steel sleeve of aluminum strip rolling mill

1. Quenching and tempering treatment (core)

quench:

Austenitization at 840-860 ℃, oil quenching after insulation (water oil dual medium quenching is used for crack prevention when the section is large).

Tempering:

High temperature tempering at 580-620 ℃, hardness HRC26-30 (balancing strength and impact resistance requirements of aluminum rolling mill).

2. Surface strengthening (optional)

Ion nitriding:

500 ℃ × 20h, surface hardness ≥ HV900, infiltration layer 0.2~0.3mm (improves wear resistance without affecting matrix toughness).

Laser quenching:

The hardness of the local guide surface is HRC50~55, with a depth of 1.0~1.5mm (precise control of deformation).

GW precision adopts centrifugal casting to guarantee the inner and outer surface of the customized sleeve is free from defects of cracks, slag inclusion and sand holes.

GW precision conduct heat treatment strictly for customized 35CrNiMo steel sleeve which have the specific demand in mechanical property.

Standard and water proof export package will be important when the customized sleeves being shipped on the sea for several days. Three layers package will avoid many accidents on the way.