Reduction Gearbox For Rod Pumping Equipment

reduction gearbox for rod pumping equipment

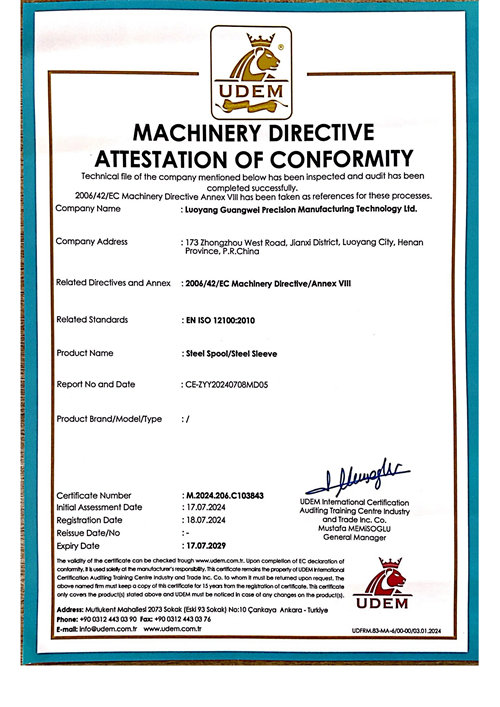

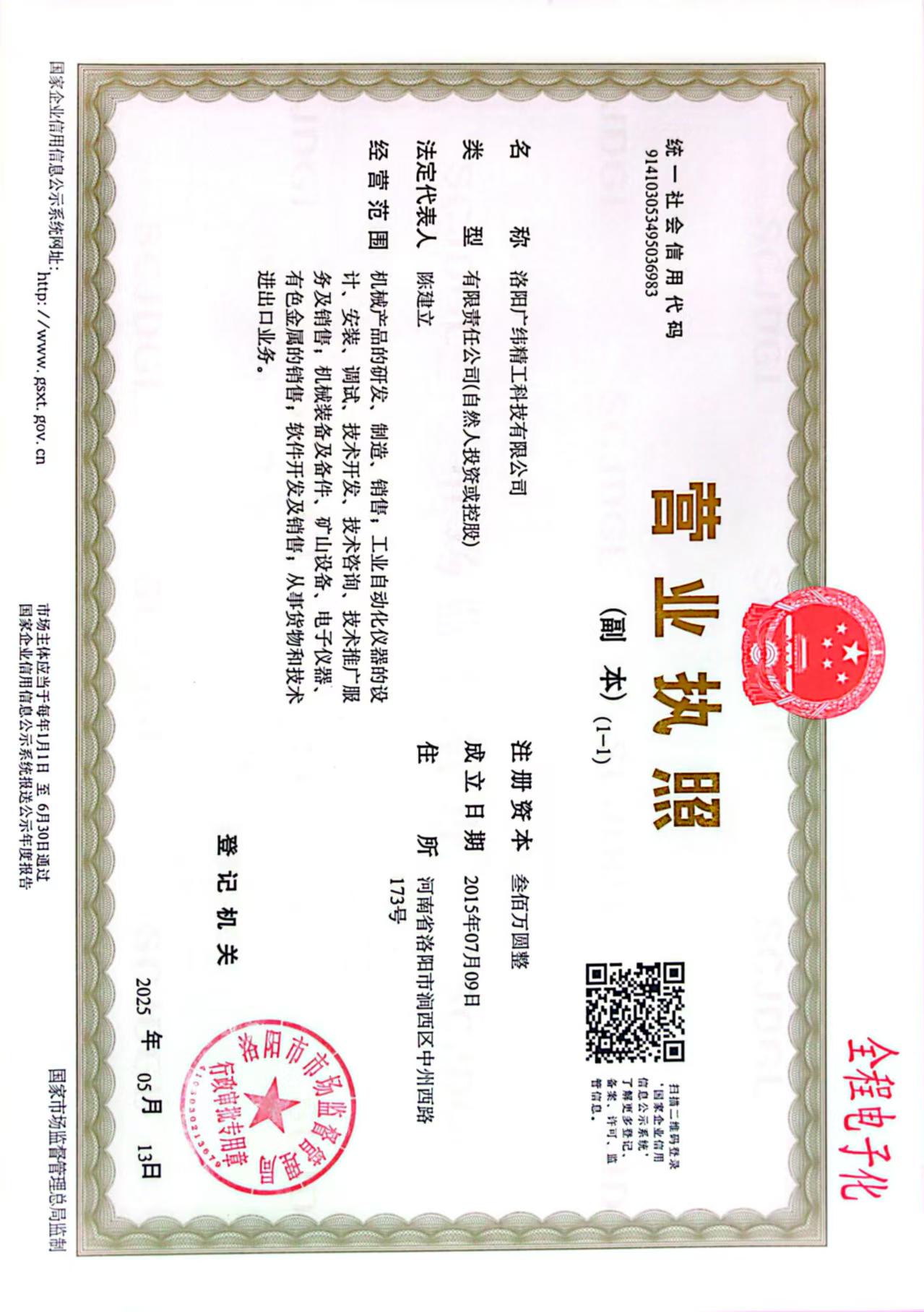

- GW Precision

- China,Luoyang

- Contractual Stipulation

- customized

- Information

reduction gearbox for rod pumping equipment

Application scenarios of reduction gearbox for rod pump equipment

1. Core functions

Torque conversion: Convert the high-speed rotation of the motor (usually 1450-1800rpm) into low-speed reciprocating motion of the sucker rod (4-12 times/minute)

Load buffering: withstand the alternating load of the sucker rod (peak torque can reach 200% of the rated value)

Continuous operation: Desert/offshore platforms operate 24/7, with a design lifespan of ≥ 10 years

2. Typical working conditions

Extreme environment:

Temperature range: -40 ℃ (Arctic) to+55 ℃ (Desert)

Sandstorm (particle concentration>1g/m ³) or salt spray (Cl ⁻ concentration>5mg/m ³)

Mechanical conditions:

Gear contact stress 600-900MPa (calculated according to AGMA 2001 standard)

Instantaneous impact load (such as impact coefficient 2.5-3.0 when wax blockage is removed)

Material selection and heat treatment of reduction gearbox for rod pump equipment

1. Gear component materials

Component material selection, heat treatment process, surface hardness

Solar/planetary gear 18CrNiMo7-6 (DIN standard) carburizing and quenching (layer depth 1.2-1.8mm) HRC58-62

Internal gear ring 42CrMo4+ion nitriding layer 0.3-0.5mm HV900-1100

Output shaft 34CrNiMo6+ultrasonic frequency quenching hardening layer depth 4-6mm HRC50-54

2. Direction of Material Innovation

Powder metallurgy gears: ASP ® 2060 (containing 3% Mo, with a 40% increase in resistance to micro pitting corrosion)

Composite box: ductile iron QT600-3+lined with 304 stainless steel (anti-corrosion and weight reduction)

The GW precision reduction gearbox for Rod Pumping Equipment is one of the crucial equipments in oilfield extraction, and its function

is to convert the input of high speed rotation into the output of lower speed, so as to realize the effective

extraction of oil wells.

In the pumping reduction gearbox, it is crucial to choose the right gear material Commonly used gear materials

include steel, aluminum alloy and copper alloy. These materials have different characteristics and have

an important impact on the performance and durability of the gearbox. The correct choice of gear

material can effectively improve the working efficiency and life of the gearbox.

Example of Technical Parameters for reduction gearbox of Rod Pump Equipment

Typical indicators of parameter items

Transmission ratio range 25:1~40:1 (multi-stage planetary gear system)

Mechanical efficiency ≥ 96% (including bearing loss)

Noise level ≤ 78dB (A) @ 1m

Forced circulation filtration of lubrication system (accuracy β ₅ ≥ 200)

The overhaul cycle of this gearbox under heavy oil extraction conditions can reach 50000 to 80000 hours, and the latest technology uses a digital twin system to predict the remaining life in real time (with an error of less than 5%).

For more technology questions, pls feel free to contact us:guangwei@gwspool.com