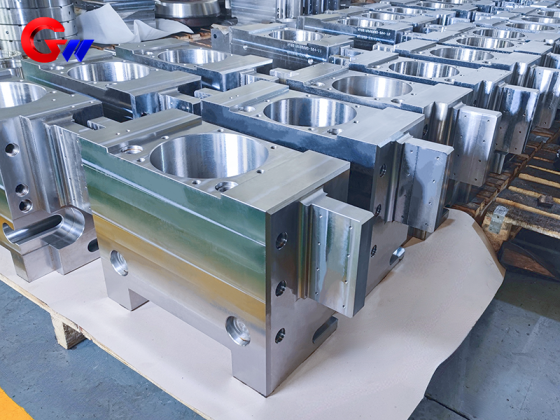

Rolling Mill Bearing Block Of Cold Mill Machine

Our advantages: high-precision intelligent CNC manufacturing equipment, high-tech staff, mature processing system, strict quality inspection process, excellent production management process, is the guarantee of high-quality products.

Due to the complex structure of GW Precision Rolling Mill Bearing Block, the bearing holes require high accuracy, so GW Precision adopted the rough process as first step and then fine machining process.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Bearing Chock is 1000 pieces

- Information

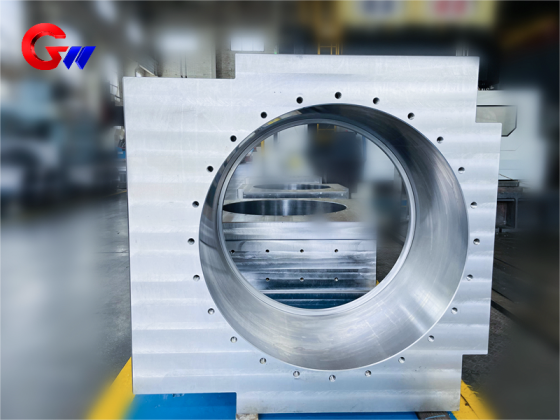

Rolling Mill Bearing Block Of Intermediate Roller Of Cold Mill Machine

Due to the complex structure of GW Precision Rolling Mill Bearing Block Of Cold Mill Machine, the bearing holes require high accuracy, so GW Precision adopted the rough process as first step and then

fine machining process.

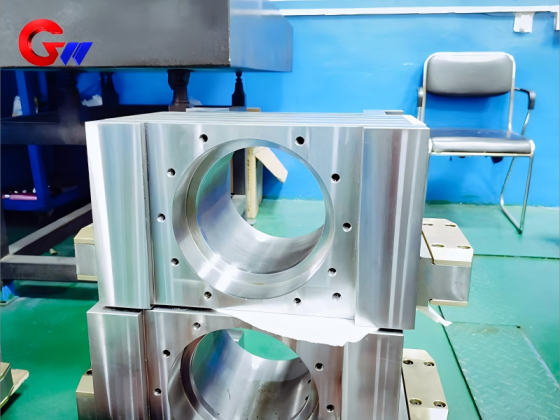

Whether cast iron or cast steel is better for GW Precision Rolling Mill Bearing Block Of Cold Mill Machine bearing housings?

The choice of Rolling Mill Bearing Block Of Cold Mill Machine material should be based on the specific

application requirements and working environment.

The bearing pedestal of cold rolling mill is a key component in the cold rolling unit, which is mainly used to support the roll, bear the rolling force and ensure the accurate operation of the roll.

Cast iron and cast steel are two commonly used materials for Rolling Mill Bearing Block Of Cold Mill Machine,they have their own advantages and disadvantages, suitable for different occasions. Cast iron bearing housings are suitable for low speeds, light loads and occasions that do not require high-precision operation due to their lower cost, higher hardness, but lower toughness. The brittleness of cast iron makes it likely to break when subjected to impact, but its hard and brittle nature can actually make cutting easier in normal cutting operations such as tapping.

Cast steel housings, on the other hand, are suitable for heavy-duty and high-speed applications due to their higher strength and toughness. Cast steel has better ductility and is less prone to fracture, but has a relatively low hardness compared to cast iron. In cutting operations, the cutting of cast steel usually produces longer chips, which may lead to increased cutting resistance, thus requiring more force during tapping and possibly resulting in higher tool wear.

The bearing seat of cold rolling mill integrates material science, heat treatment process and high-precision processing technology, and its performance directly affects the stability of rolling mill and product accuracy. Industry leaders (e.g. SKF, Simaks, etc.) further optimize the design through simulation analysis (e.g. FEA stress simulation).

When selecting GW precision Rolling Mill Bearing Block Of Cold Mill Machine materials, other factors such as the working environment and service life should also be considered. For example, if the working environment is harsh, it may be necessary to consider using a bearing housing made of stainless steel or plastic to enhance corrosion and high temperature resistance.

The final choice should be based on the equipment load, speed, working environment and service life and otherfactors to weigh. For example, under high loads and high speeds, cast steel Rolling Mill Bearing Block Of Cold Mill Machine is widely used because of its superior overall performance.