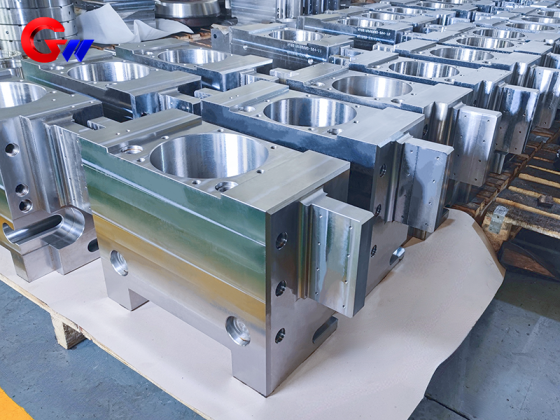

Rolling Mill Bearing Block Of Working Roller Of Hot Mill Machine

GW Precision has formed a set of mature mechanical processing technology for the production of bearing housing through the accumulation of long-term experience.

GW Precision rolling mill bearing block often use the following materials:

1. Cast steel: durable and high price. Rolling mill bearing housings are mainly made of cast steel.

2. Gray cast iron: economical and cheap, but not durable .

3. Ductile cast iron: has a certain degree of strength, plasticity and toughness .

4. Stainless steel: This material is being used on the work conditions where there is corrosion .

5.Zinc alloy: lightweight, easy to install, corrosion-resistant, maintenance-free, and has vibration and

shock absorbing properties.

Choosing the right material will ensure that the mill bearing housing can still maintain good performance

and long service life under harsh working conditions.

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity of Steel Spool is 4000 pieces

- Information

Rolling Mill Bearing Block Of Working Roller Of Hot Mill Machine

GW Precision has formed a set of mature mechanical processing technology for the production of

bearing housing through the accumulation of long-term experience.

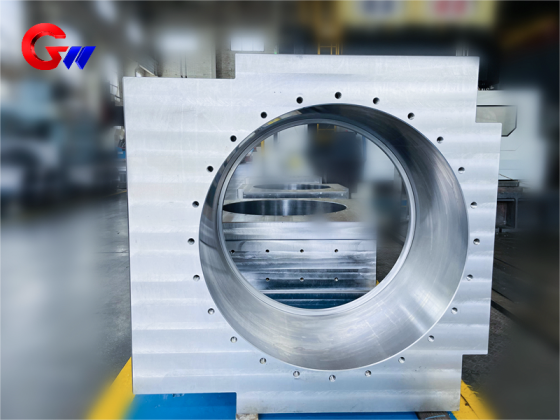

The work roll bearing housing of hot rolling mill is one of the core components of rolling mill, which directly bears rolling force, impact load and high temperature environment. Its design and manufacture shall take into account high strength, wear resistance and thermal stability.

Application Scenarios of Bearing housing of Work Roll Mill of Hot Rolling Mill

Load characteristics

It can bear rolling force (up to thousands of tons) and alternating impact load (such as the moment of steel bite).

Operating temperature: 150~300 ℃ (hot rolling high temperature radiation+frictional heat generation).

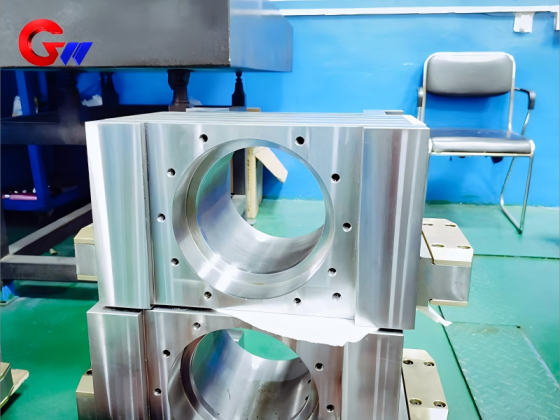

Working condition environment

High pressure water descaling scale splattering, rolling oil/emulsion corrosion.

Mechanical wear caused by frequent roll change (mating surface between bearing housing and roll neck).

Functional Requirements

Precisely support the work roll to ensure the roll system stiffness and rolling accuracy (such as shape control).

Material Selection of rolling mill bearing housing

Main material

High Strength Cast Iron (Mainstream Option):

Brand: HT250, QT500-7 (nodular cast iron).

Advantage: good shock absorption, casting performance and low cost.

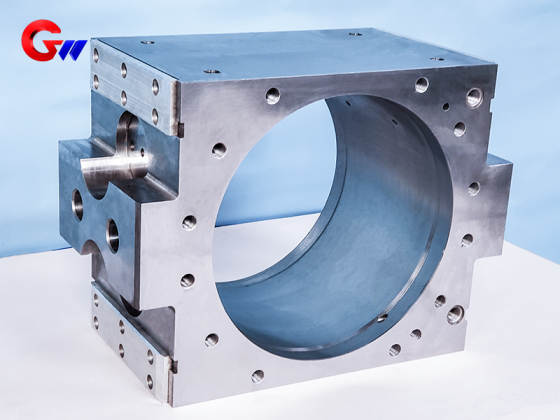

Cast Steel (Heavy Duty Service):

Brand: ZG270-500, ZG35CrMo (weldability better than cast iron).

Forged Steel (Ultra High Strength Requirement):

Brand: 42CrMo, 34CrNiMo6 (requiring tempering and heat treatment).

Wear-resistant parts

Bearing Liner/Slide Plates:

Materials: high chrome cast iron (Cr15Mo3), copper alloy (ZCuAl10Fe3).

Surface treatment: laser cladding (WC-Co coating) or plasma spraying.

Fasteners

Bolt: 42CrMo (Grade 10.9 and above), tensile strength ≥ 1040MPa.

Heat Treatment Process of rolling mill bearing housing for Hot Rolling Mill

Iron casting parts

Annealing: eliminate casting stress (500~600 ℃ insulation and slow cooling).

Surface quenching: high-frequency quenching of guide rail surface (hardness HRC45-50, depth 2~3mm).

Cast Steel/Forged Steel Parts

Hardening and tempering treatment: quenching (850 ℃ oil cooling)+high temperature tempering (550~600 ℃), hardness HB250-300.

Nitriding treatment: gas nitriding of bearing mating surface (hardness ≥ HV800, layer depth 0.3mm).

Wear-resistant coating

Low temperature tempering (200 ℃) after laser cladding to reduce internal stress of coating.

GW Precision rolling mill bearing block often use the following materials:

1. Cast steel: durable and high price. rolling mill bearing block are mainly made of cast steel.

2. Gray cast iron: economical and cheap, but not durable .

3. Ductile cast iron: has a certain degree of strength, plasticity and toughness .

4. Stainless steel: This material is being used on the work conditions where there is corrosion .

5.Zinc alloy: lightweight, easy to install, corrosion-resistant, maintenance-free, and has vibration and

shock absorbing properties.

Choosing the right material will ensure the rolling mill bearing block can still maintain good performance

and long service life under harsh working conditions.