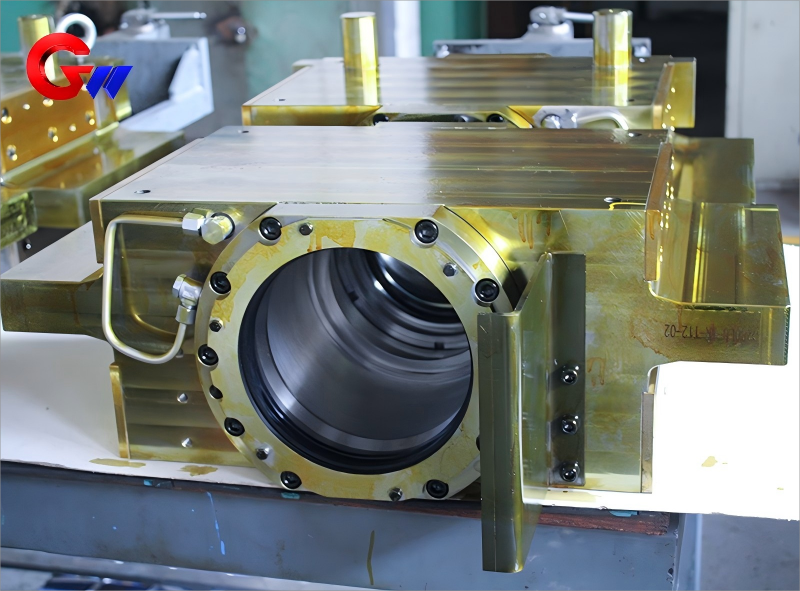

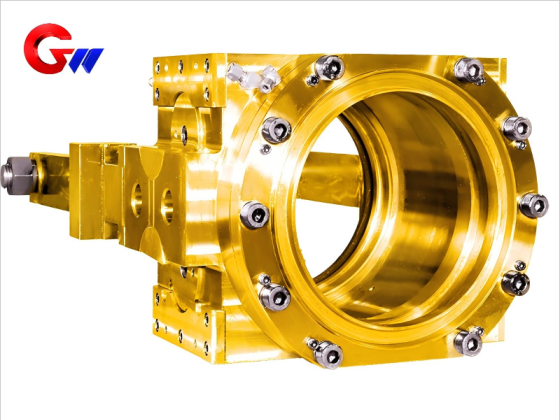

The bearing box of the supporting roller on the transmission side of the hot rolling mill

Application scenarios of the support roller bearing box on the transmission side of the hot rolling mill

Core functions

Heavy load support: withstand rolling force (up to 3000-8000kN on one side) and transmit it to the frame.

Precise guidance: Ensure that the radial runout of the support roller is ≤ 0.03mm (guaranteeing a thickness tolerance of ± 0.1% for the strip steel).

Lubrication management: Integrated oil air lubrication system (pressure 0.2-0.5MPa), suitable for high-speed rolling (≤ 15m/s).

Typical compatible models

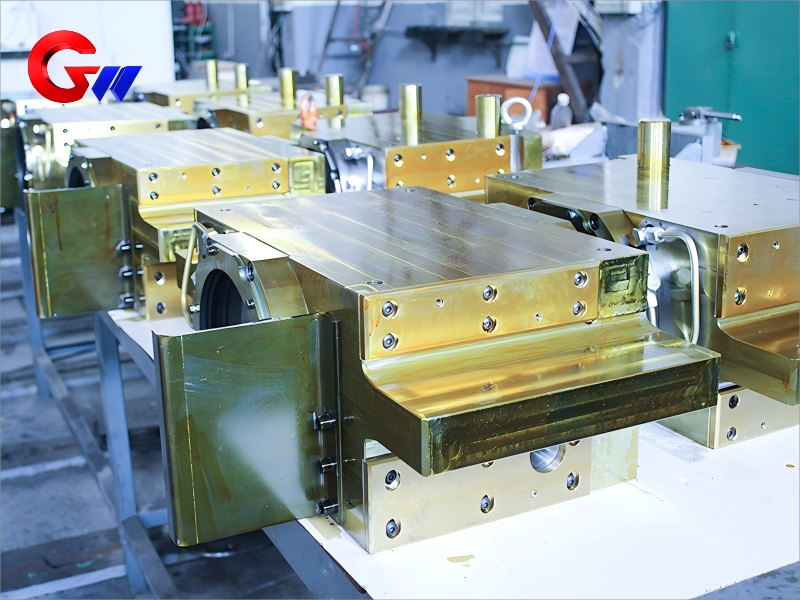

Four roll hot rolling mill: used for the production of carbon steel and stainless steel plates and strips (thickness 2-25mm).

Reversible roughing mill: capable of withstanding frequent reversing impact loads (rolling force fluctuations ± 20%).

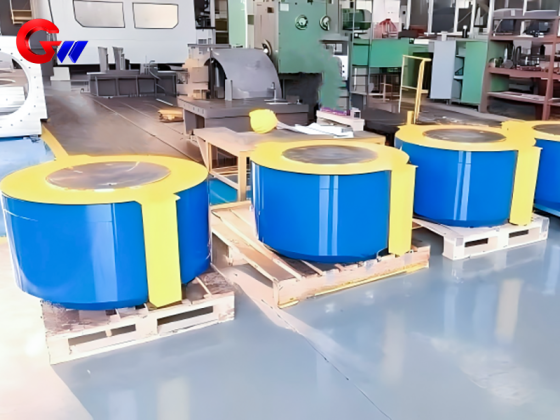

- GW Precision

- China,Luoyang

- Contractual Stipulation

- Anual Capacity is 500 pieces

- Information

The bearing box of the supporting roller on the transmission side of the hot rolling mill

Luoyang Guangwei precision technology co.ltd,. locates on the west side of the Henan Diesel plant, one of ten greatest plant during the First Five-year Plan in Henan province. Support roller bearing box is one of our main products.

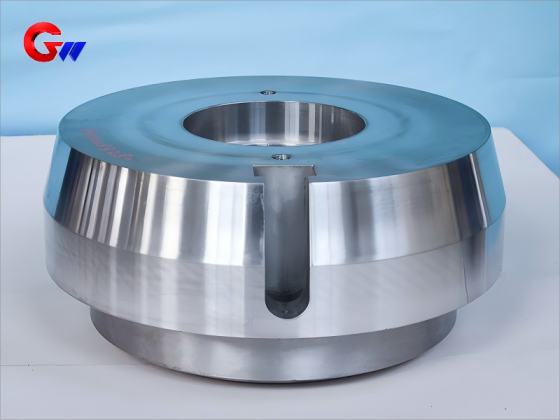

Material characteristics of the support roller bearing box on the transmission side of the hot rolling mill

Main material

Cast steel grade: ZG35CrMoV (optimized composition)

|Element | C 0.30-0.38 | Cr 0.8-1.2 | Mo 0.2-0.4 | V 0.1-0.3|

Performance advantages:

High temperature strength (σ ₀. ₂ ≥ 450MPa at 500 ℃);

Thermal fatigue resistance (crack length ≤ 0.5mm after 1000 thermal cycles).

Key component materials

Hardness of component materials after heat treatment

Support roller bearing box body ZG35CrMoV quenched and tempered HB 260-300

Wear resistant lining plate 42CrMo surface quenched HRC 50-55

Sealing ring 304 stainless steel solution treatment HB 180-200

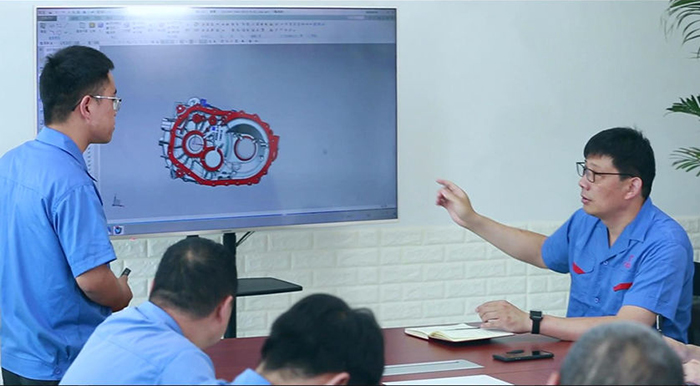

Recent years, support roller bearing box becomes the main product of our company. To fully upgrade the equipment, the company spent a huge sum of money to buy vertical processing center, longmen processing center, horizontal processing center, achieving the PVC automatic processing mode to support roller bearing box. And through the computer programming optimization process, the company's process refines and reasonable arrange the process plan, developing a set of mature bearing seat processing process; Effectively improve the processing quality of support roller bearing box.

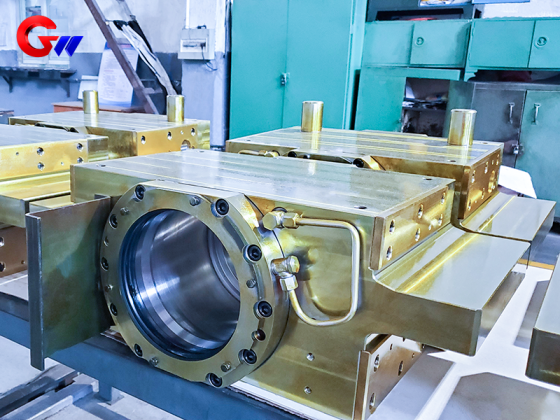

Inspection procedure for the hot rolling mill bearing box

material inspection

Spectral analysis: Deviation of each element ≤ ± 0.03% (handheld XRF instrument);

Ultrasonic testing: accepted according to EN 12680-3 Class 2.

dimension measurement

Project tolerance testing equipment

Concentricity of bearing holes ≤φ 0.02mm Three coordinate measuring machine

Installation surface flatness ≤ 0.03mm/m laser plane interferometer

The above advantages of our company in the production of bearing housing make our company in the advanced position in the production of bearing box products domestically.production orders in the industry leading. The staff of the company will learn the advanced management ideas of the same industry in the future production and processing, so that the company can better serve customers and grow together with customers.

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any Hot Rolling Mill Machine Of The Transimit Side Supporting Roller Bearing BOX repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!

guangwei@gwspool.com or +86-379-64593276